The Industrial Internet of Things is the enabling boom that will change business as we know it. It will affect every industry and raise the bar for customer experience and service.

What is IIoT?

The industrial Internet of Things is the convergence of sensors, software, and connectivity technologies that revolutionize how manufacturers perform operations and get real-time feedback from assets such as machinery, production lines, and energy sources.

The Industrial Internet of Things (IIoT) extends the internet to physical devices and infrastructure. The most notable example of an IIoT solution is the industrial automation control system based on wireless connectivity technology that offers remote monitoring, control, data collection, and reporting solutions. These industrial IoT solutions collect data typically related to performance and health indicators, which can be used in making operational decisions with the help of operational technology and improving efficiency.

This can enable companies to optimize their manufacturing processes and reduce costs through improved operational efficiency. The benefits of IIoT include cost savings at every level: from capital investments to operating expenses. This study looks at the factors driving this growth in detail.

Industrial IoT Market Outlook 2018-2022

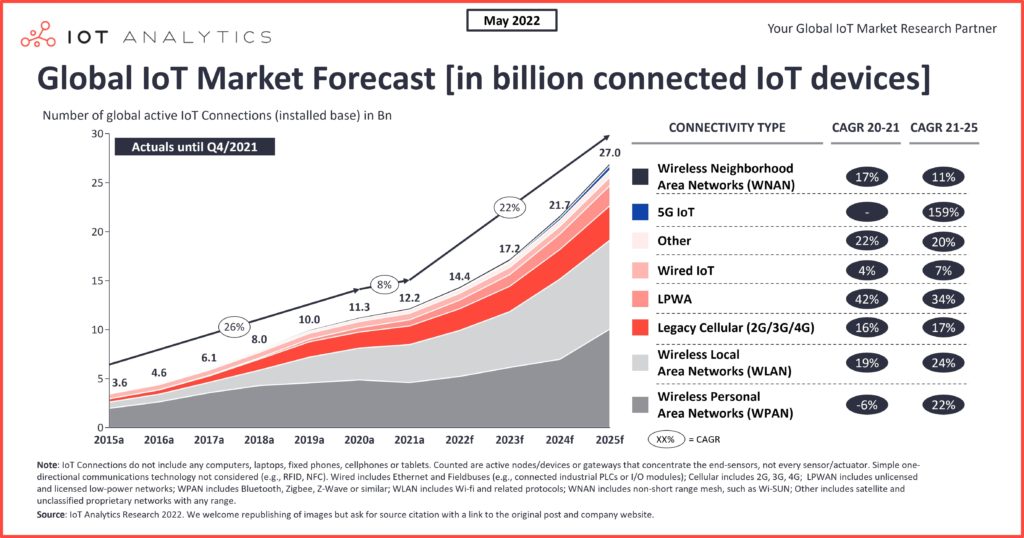

According to the Industrial Internet of things market analysis, it is expected to grow from $22.7 billion in 2018 to $28.9 billion by 2022, at a CAGR of 5.1%. The growth is driven by the increase in demand for smart industrial systems and the need to improve productivity and reduce costs.

The IoT market segmentation is into intelligent process automation, smart sensors and actuators, machine-to-machine communication, and others.

The intelligent process automation segment is expected to contribute the largest share of the Industrial IoT market during the forecast period. We discussed the advantages and disadvantages of automation testing earlier. The key factors driving this growth include increasing adoption of advanced technology across industries, growing demand for cost-effective solutions from various business verticals, and increasing emphasis on safety & security in manufacturing facilities across multiple industries.

However, some factors will hamper the growth of this market during the forecast period. These include an insufficient number of qualified professionals with relevant skillsets required for designing & developing such products & services; high per capita income levels, which makes it difficult for manufacturers to adopt these technologies; high initial investment costs associated with deploying these products & services; and high total cost of ownership per unit due to their long-life cycle without any maintenance cost involved after deployment.

Impact of COVID-19 on the Industrial IoT Market

The global COVID-19 pandemic has impacted the industrial IoT market, which is expected to experience a significant increase in demand for connected devices. This will create new opportunities for manufacturers to obtain better insights into their products and processes and enable them to develop new applications that can improve worker safety and productivity.

As a result, the COVID-19 pandemic has created an opportunity for companies to develop new products and services to help them manage their businesses. Our article how technology is helping in COVID-19 will let you understand it better. The impact of COVID-19 on the industrial IoT market includes:

- Reduced sales of industrial systems and equipment, which may lead to reduced revenue or profitability.

- Increased costs associated with operating and maintaining industrial systems and equipment, which may lead to reduced profits.

- Increased capital investment, which can be difficult for companies to fund on their own or access from investors.

- Reduced confidence in the safety of industrial systems and equipment purchased or used by customers or employees.

The current rate of decline is expected to continue until 2021, at which point it will begin to improve. However, even as the market starts to recover, long-term effects on sales are likely: consumers are likely to be wary of purchasing products with no proven efficacy against COVID-19 and may need more confidence in them.

Key Players & Market Share Insights

Industrial IoT shares a lot of similarities with the connected home market. Both are characterized by their enormous growth, as well as their high-tech nature and complex user experience. According to Gartner, the industrial internet of things market size is expected to grow at a compound annual growth rate (CAGR) of 20% from 2016 through 2020, reaching $2.7 billion by 2022:

- Various factors: drive this growth

- The need to monitor and control production processes in a more efficient manner

- The desire to reduce costs, improve product quality and increase customer satisfaction

- The use of advanced technologies such as drones and smart sensors for remote monitoring and management of assets (e.g., vehicles, buildings)

The industrial internet of things companies are:

- Intel Corporation

- Cisco Systems, Inc

- MediaTek Inc

- Freescale Semiconductor, Inc

The Internet of Things (IoT) is a new technology that connects physical devices to the internet. The potential for IoT is vast, as it can connect machines, vehicles, buildings, and other devices into a network.

Industrial IoT market forecast

The Industrial IoT market is expected to grow at a CAGR of 14.9% during 2019-2024. The factors driving this growth are the increasing demand for industrial machines and equipment, the rising adoption of cloud computing, and the growing acceptance of artificial intelligence (AI) and machine learning (ML).

According to Frost & Sullivan’s Global Market Insights Report: “Industrial IoT Market by Solutions (Platforms, Services, Data Analytics & Applications), Industry Verticals (Automotive Manufacturing, Aerospace & Defense Manufacturing & Machinery Manufacturing), and Geography – Global Forecast to 2024”, the Global Industrial IoT market was valued at USD 3.2 billion in 2018, and it is expected to grow at a CAGR of 14.9% during the period 2019-2024.

Frost & Sullivan’s report includes a detailed analysis of key market growth trends. These include the increased adoption of new technological smart devices in automobiles and other industries, the increasing demand for smart sensors, the growing need for smart factories, rising integration with different verticals such as healthcare and manufacturing, and an increase in the number of projects implemented according to standards such as ISO 26262.

Conclusion

Learning how to bring together IoT technology with existing manufacturing assets enables manufacturers to be more agile, better manage their supply chain, monitor assets in real time, and provide superior customer service. Connected sensors can provide valuable data to enable manufacturers to improve their operations by eliminating waste.